Soft Drink Manufacture - Preparation of Sugar Syrups

VẤN ĐỀ CÓ THỂ GẶP PHẢI

- Liquid sugar can be considerably more expensive than granulated sugar.

- Dissolving of granulated sugar by simple agitation is a slow process.

- Conventional agitators cannot dissolve high concentrations of sugar at ambient temperatures.

- Heating the water to aid solution adds to costs and is energy inefficient.

- The cooling process further adds to costs and process time.

- Crystallization of the syrup can occur during heating/cooling.

- Incomplete solubilization can lead to sedimentation or even blocking of vessel outlets.

GIẢI PHÁP

A Silverson High Shear Mixer can substantially reduce mixing times and eliminate the need for heating the water.

This can be achieved with in-tank Batch Mixers or by adding a Silverson In-Line Mixer to the existing process.

ƯU ĐIỂM

- The combination of granule size reduction and vigorous mixing dramatically reduces mixing times.

- A 66% sugar syrup can be produced at ambient temperature.

- Increased versatility allows the manufacturer to use sugar in granulated or syrup form.

- A Silverson mixer can also disperse and hydrate thickening and stabilizing agents such as CMCs and Xanthan gum in a fraction of the time taken by other means.

There are several products in the Silverson range suitable for this application, the selection of which is dictated by individual process requirements including batch size.

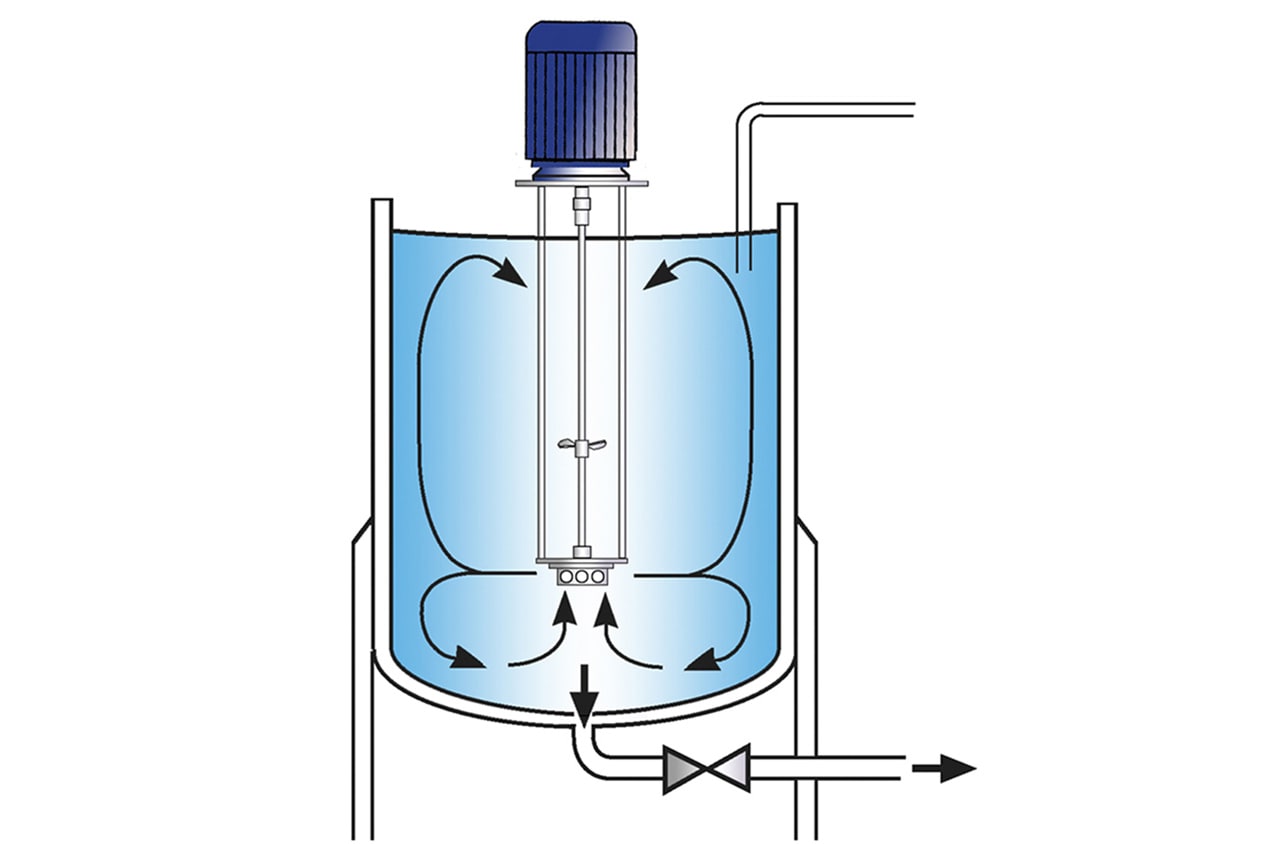

High Shear Batch Mixers

- Suitable for batch sizes up to 500 US gallons

- Many units can be used on mobile floor stands

- Small units available for R&D and pilot production

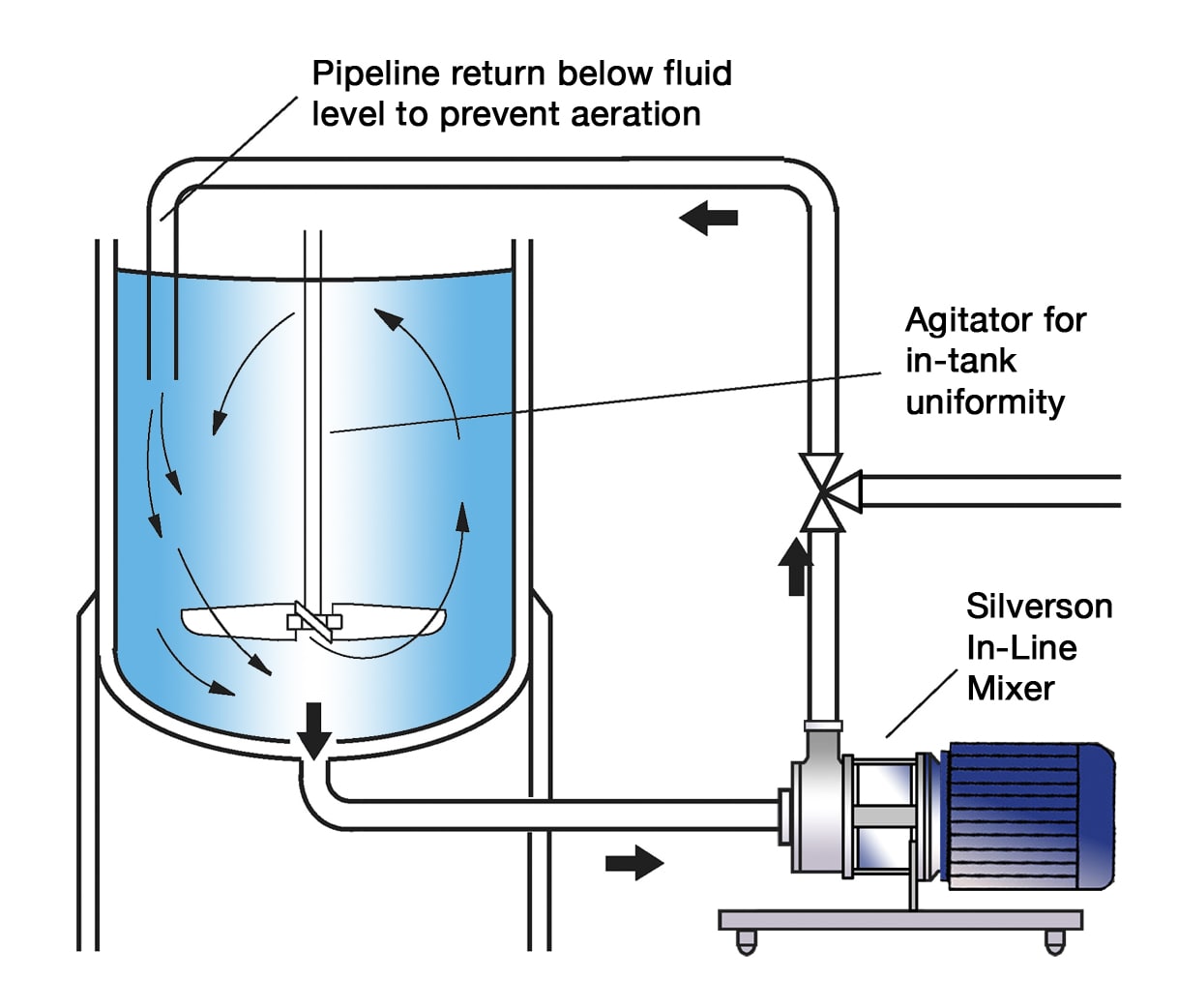

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to an existing plant

- Self-pumping

- Can be used to discharge vessel

- Ultra Sanitary models available

- High viscosity models available

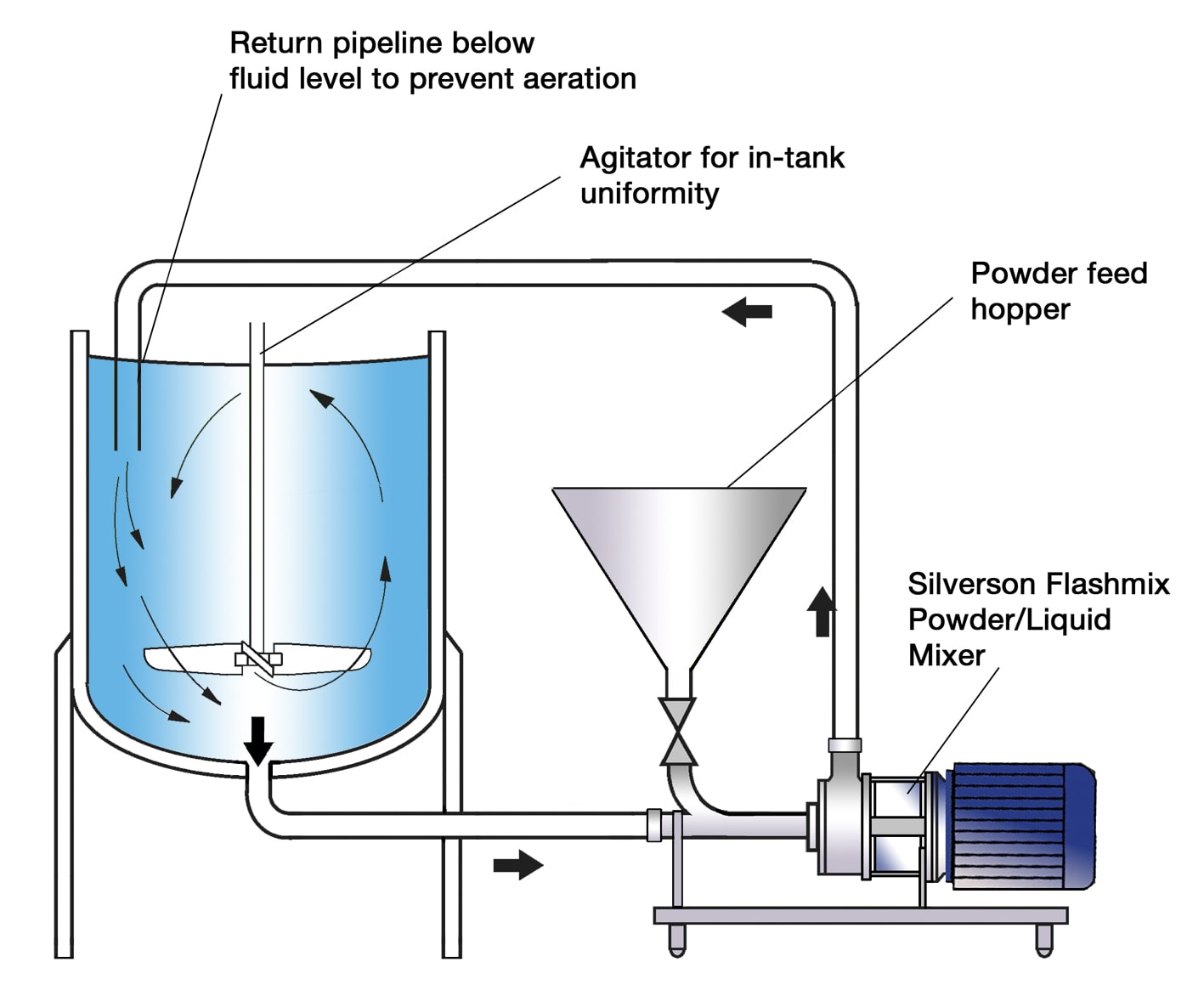

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powders

- Minimized aeration

- Minimized cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required

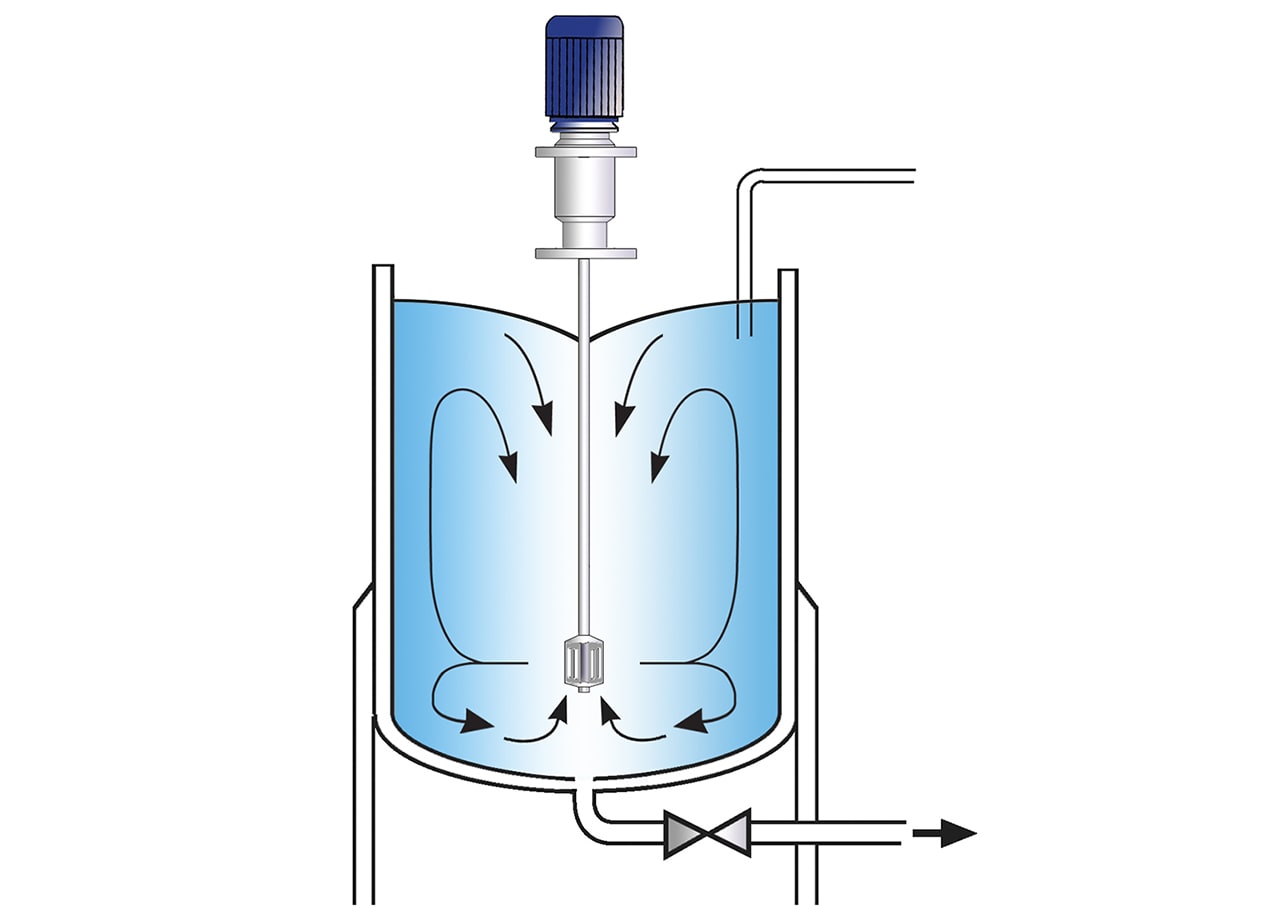

Silverson Ultramix

- Ultra Sanitary CIP design

- Excellent in-tank movement

- Capable of rapidly incorporating large volumes of powders

- Ideal for higher viscosity mixes

- Low maintenance

CALL MR VIET

0986817366

Không có nhận xét nào:

Đăng nhận xét