VẤN ĐỀ

- High Active Surfactants and water are of widely differing viscosities. If surfactants are pumped into the water in the vessel, they are not easily blended by conventional agitators. This can lead to globules of surfactant remaining undiluted or being partially diluted.

- Long process times are required to ensure a uniform product.

- Some formulations are too viscous for conventional mixers and centrifugal pumps.

- If the concentration on dilution exceeds 27%, SLES forms a highly viscous gel.

- Introduction of air greatly increases viscosity, therefore aeration must be avoided.

GIẢI PHÁP

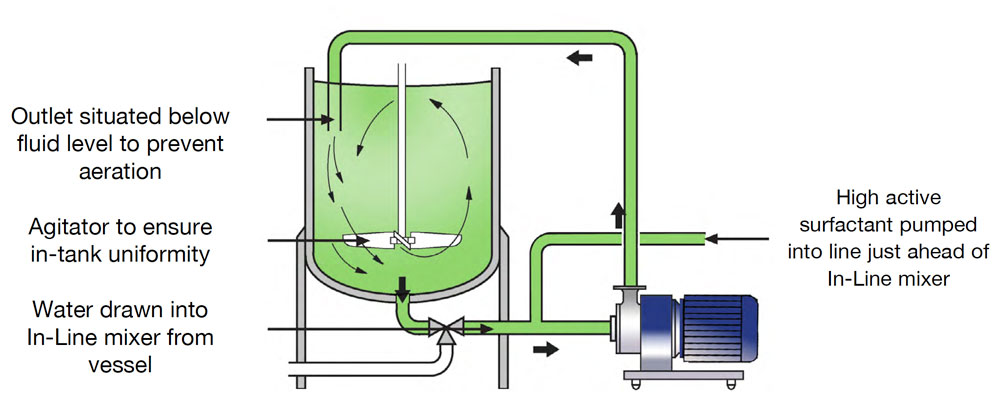

Batch Systems

Dilution is best carried out using a high shear In-Line mixer. A Silverson In-Line mixer can be used as illustrated in figure 1 below. Water is charged into the vessel and recirculated by the self-pumping Silverson In-Line mixer. The High Active Surfactant is pumped into the water stream immediately prior to the In-Line mixer. The mixer's rotor/stator workhead ensures a uniform mix which is then recirculated back into the vessel.

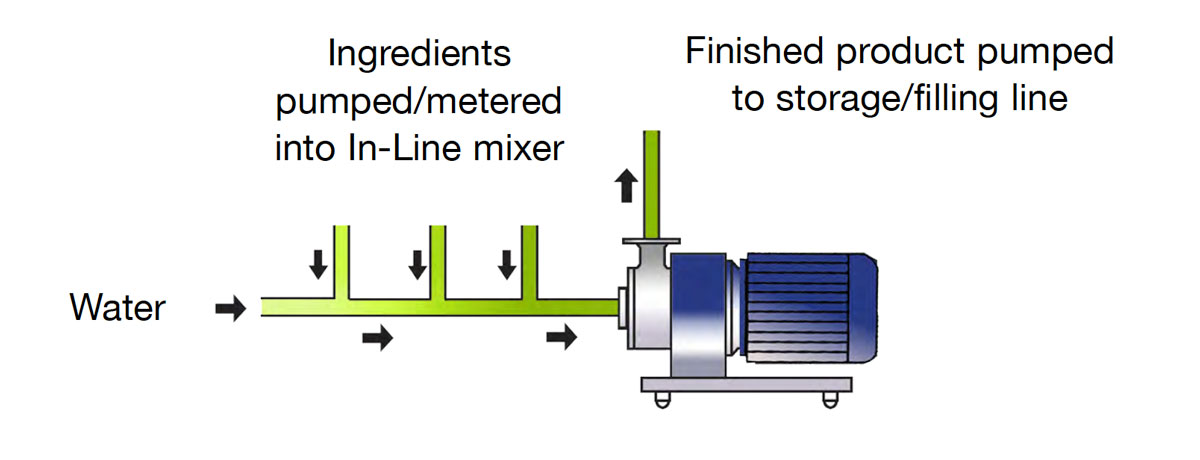

Continuous Systems

All ingredients are metered into a Silverson Multi-stage In-Line mixer for continuous, single pass dilution.

Không có nhận xét nào:

Đăng nhận xét