VẤN ĐỀ GẶP PHẢI

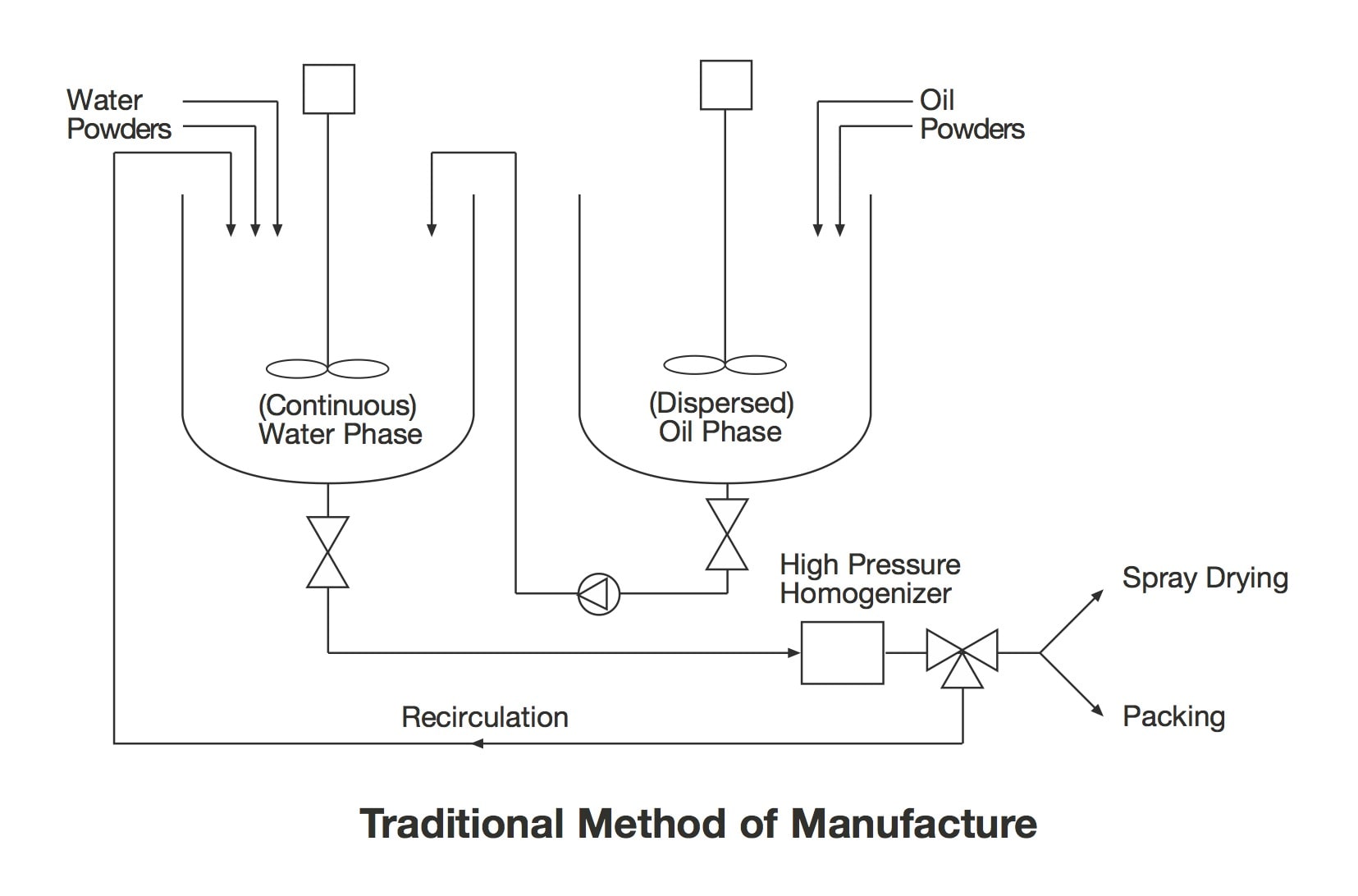

Using conventional agitators, some aspects of this process present considerable difficulty to the processor:

- Hydration of gums and thickeners is one of the most difficult mixing operations. In some cases the solution has to be agitated for a long period to ensure the gum is fully hydrated.

- Agglomerates can easily form. These are not easily dispersed using conventional agitators.

- Partially hydrated material can build up on the shaft of the mixer and on the vessel wall.

- A uniform pre-emulsion is required by the high pressure homogenizer. This is not possible using conventional agitators.

- This will result in the product having to be passed several times through the high pressure homogenizer in order to obtain the desired globule size.

ƯU ĐIỂM

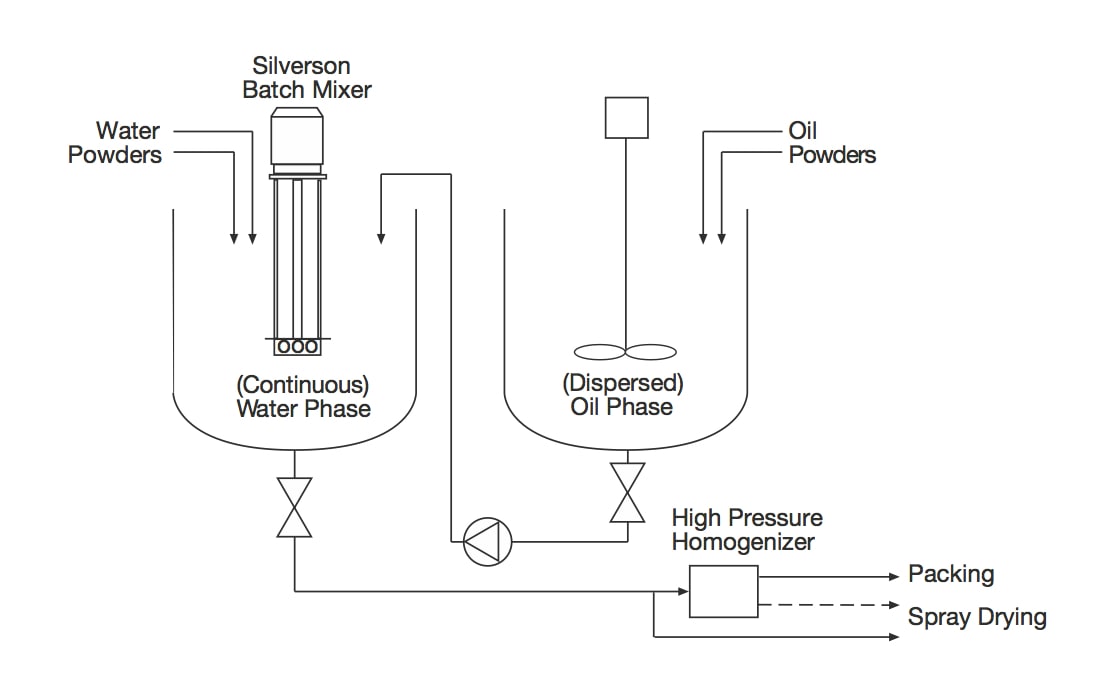

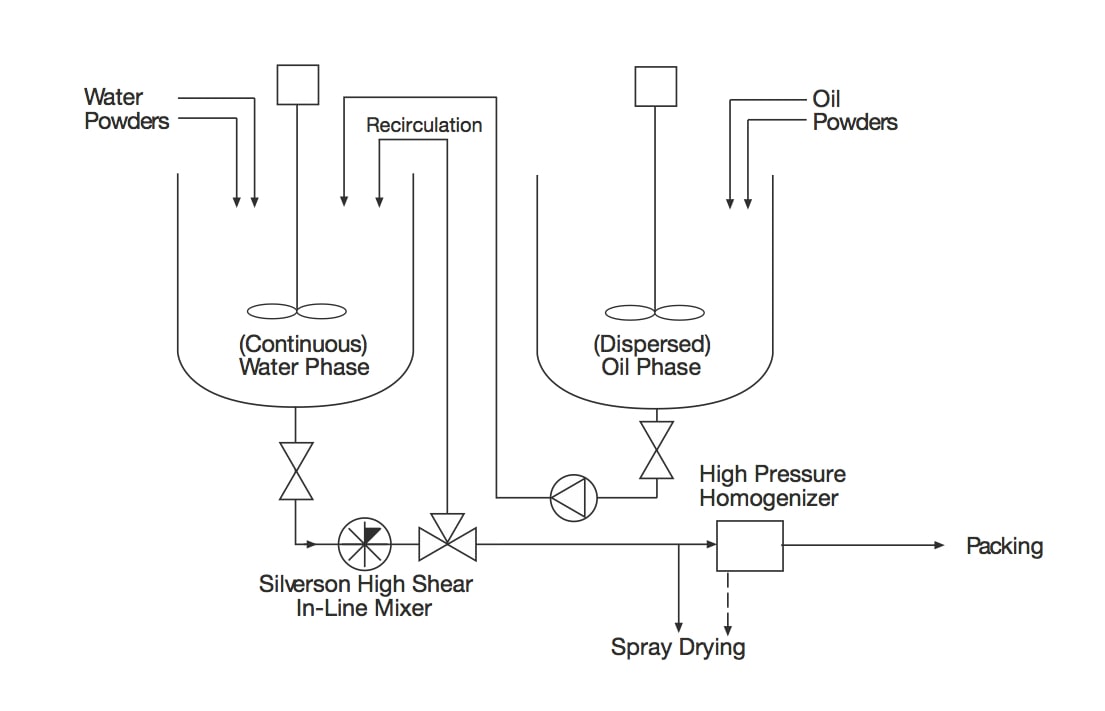

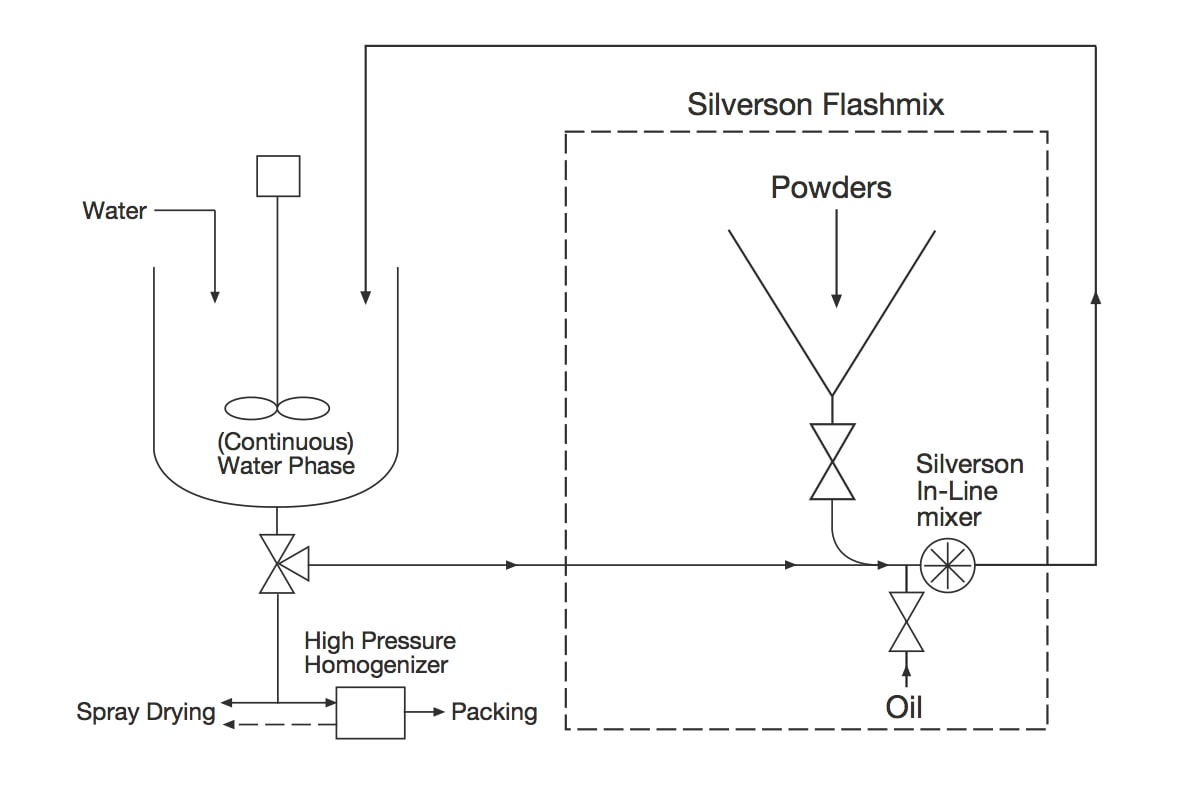

- After processing with a Silverson mixer, a single pass through a high pressure homogenizer is normally sufficient to achieve the end product.

- The high pressure homogenizer can normally be eliminated for spray-dried products.

- Typically a globule size of 5-7μm is achievable with a Silverson high shear mixer.

- Maximized yield of raw materials as thickening agents are fully hydrated and other ingredients fully dispersed.

- Consistent product quality.

- Agglomerate-free mix.

- Stable emulsion.

- Rapid mixing times.

The batch size, formulation, type of ingredients used and the viscosity of the end product dictates which machine from the Silverson product line is suited to individual processing requirements.

High Shear Batch Mixers

- Suitable for batches of up to 400 US gallons

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to existing plant

- Self-pumping

- Can be used to discharge vessel

- Ultra Sanitary models available

- High Viscosity models available

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powders

- Minimized aeration

- Minimized cleaning requirements

- Minimum operator input required

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

Không có nhận xét nào:

Đăng nhận xét