The Process

A typical manufacturing process would be as follows:

- Water is metered into the process vessel. This is often heated to around 130-140℉ (55-60℃) to aid dilution/hydration of other ingredients.

- The first ingredient added is normally the surfactant, as other additives, particularly those which affect viscosity, can make dilution of the surfactant more difficult.

- Conditioners and other ingredients are added.

- pH is adjusted to the required level.

- Sodium chloride or other viscosity modifiers are added last, along with color and fragrance.

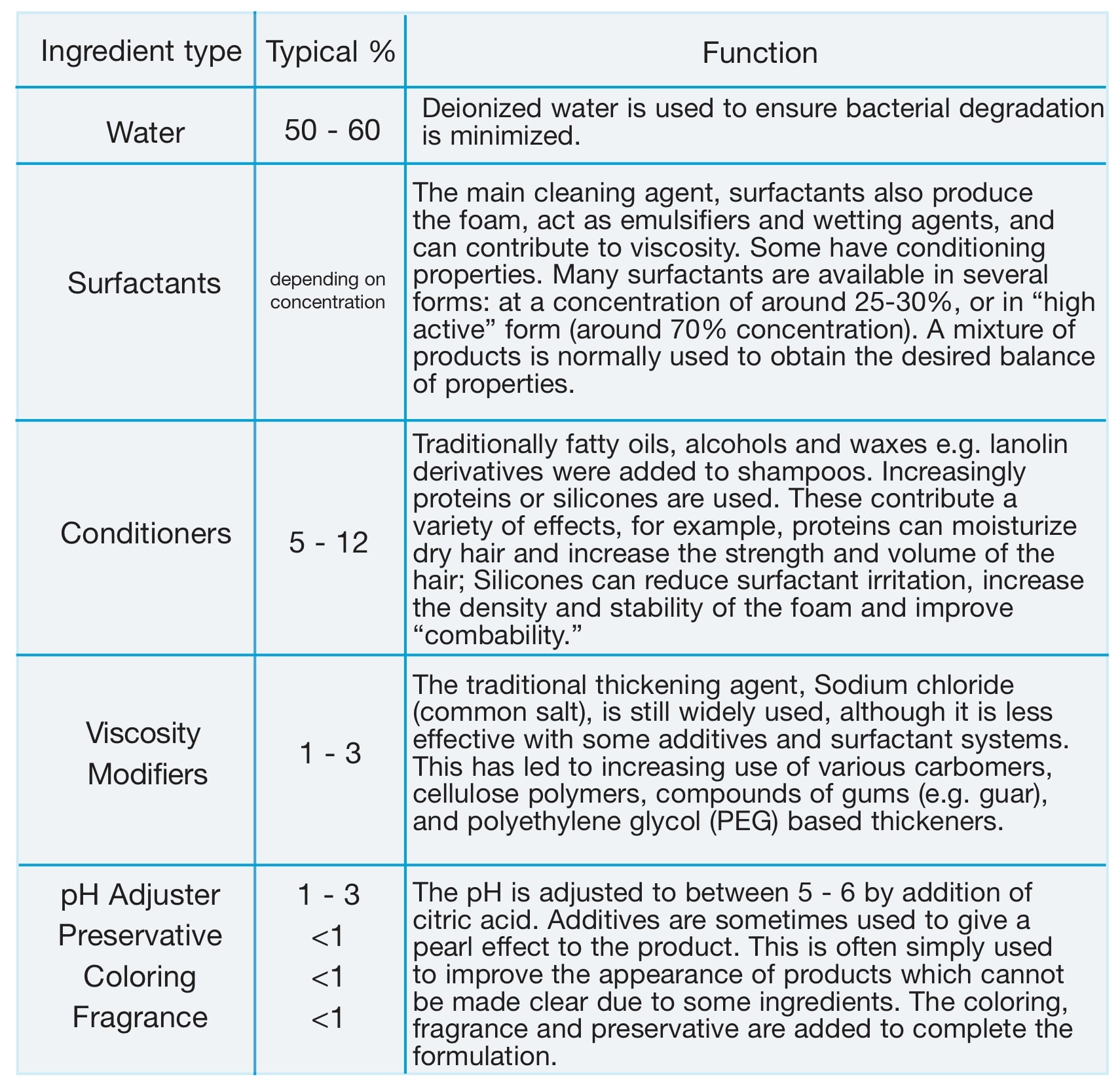

Formulations vary widely, however, the range of ingredients used can be summarized in the following table:

The Problem

A number of problems can be encountered when using conventional agitators:

- Aeration must be avoided, as this can lead to clouding of clear shampoos, and problems where packaging is filled by volume rather than weight.

- “High Active” products require special handling, see Application Report “Dilution of High Active Surfactants.”

- Silicones are immiscible with water and can be chemically incompatible with some surfactants, making them very difficult to emulsify or suspend.

- Agitators do not produce sufficient shear to reduce silicones to the finest possible droplet size and obtain a stable emulsion/suspension. They will tend to vortex, increasing aeration.

- Many ingredients have a much higher viscosity than water. When blending these with an agitator, the higher viscosity material can form globules which are simply washed around without being diluted/dispersed.

- Thickening agents such as carbomers, and cellulose or gum based products may require high shear mixing to be “activated.”

- The addition of sodium chloride becomes increasingly difficult as the viscosity rises.

- Vigorous agitation is required to overcome these problems, however, with conventional agitators this can lead to aeration.

The Solution

Stage 1

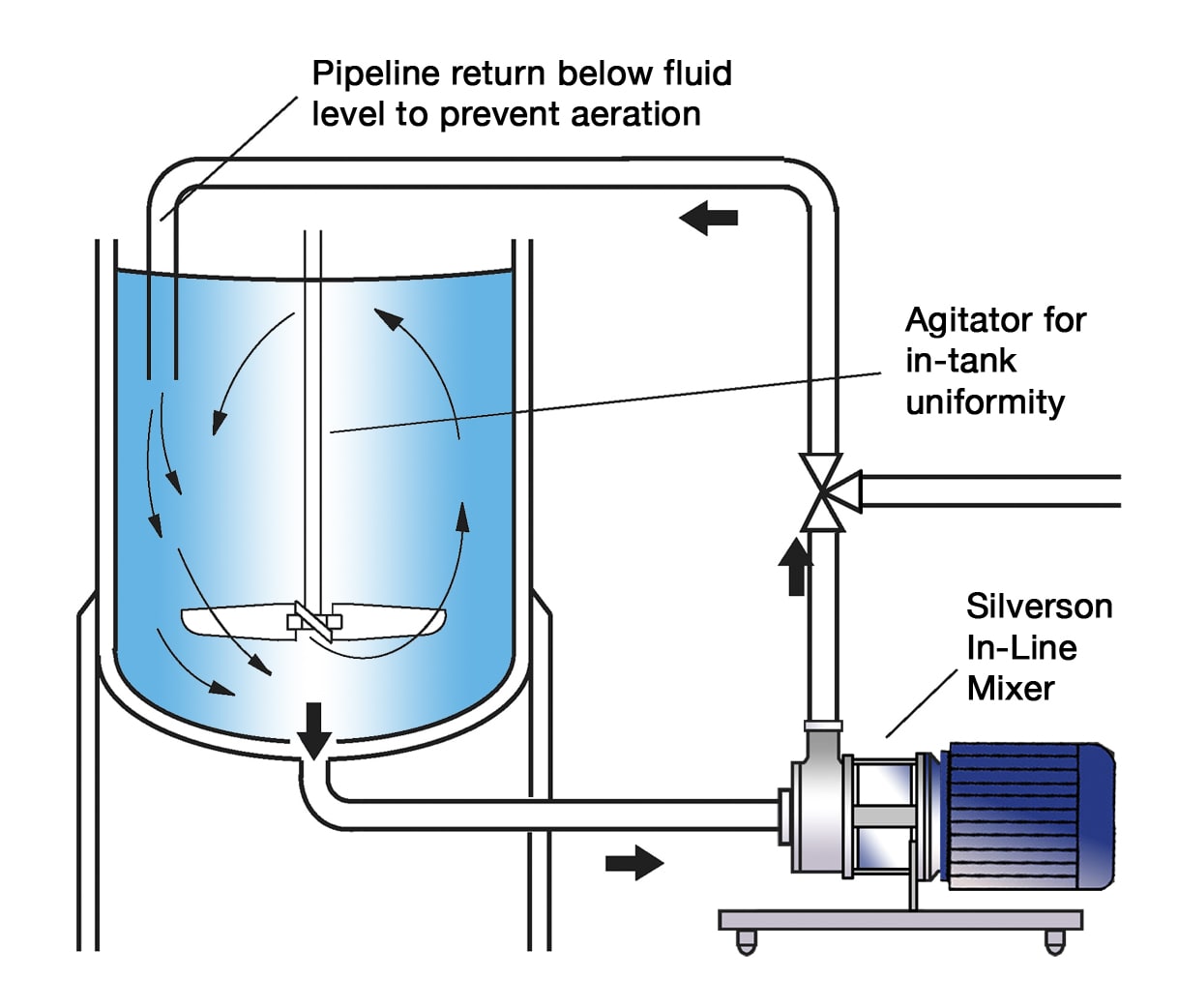

The vessel is charged with water. The in-tank agitator and In-Line mixer are started, and the surfactant and other ingredients are added in the order specified. The powerful suction created by the In-Line mixer draws the materials through the pipeline into the rotor/stator workhead.

Stage 2

Centrifugal force drives the materials to the periphery of the workhead where they are subjected to intense high shear in the gap between the rotor and stator.

Stage 3

The product is forced out through the stator and recirculated back to the process vessel as fresh material is drawn into the workhead.

The Advantages

- The high shear mixing action of a Silverson can rapidly blend liquids of widely differing viscosities.

- The In-Line mixer, pipework and vessel form a closed system, eliminating aeration.

- Dramatic reduction in mixing times.

- Significantly better yield of thickening agents than can be achieved by traditional methods.

- Consistent product quality and repeatability.

The following Silverson machines are used for this application, the suitability of which is dictated by factors including batch size, formulation and viscosity of the end product.

High Shear In-Line Mixers

- Can be used for recirculation or continous blending

- Ideal for larger batches

- Easily retro-fitted to existing process

- Aeration-free

- Self-pumping

- Ingredients can be added via a manifold for automated processes

- Can be used to discharge vessel

- Multistage units available

- Ultra Sanitary units available

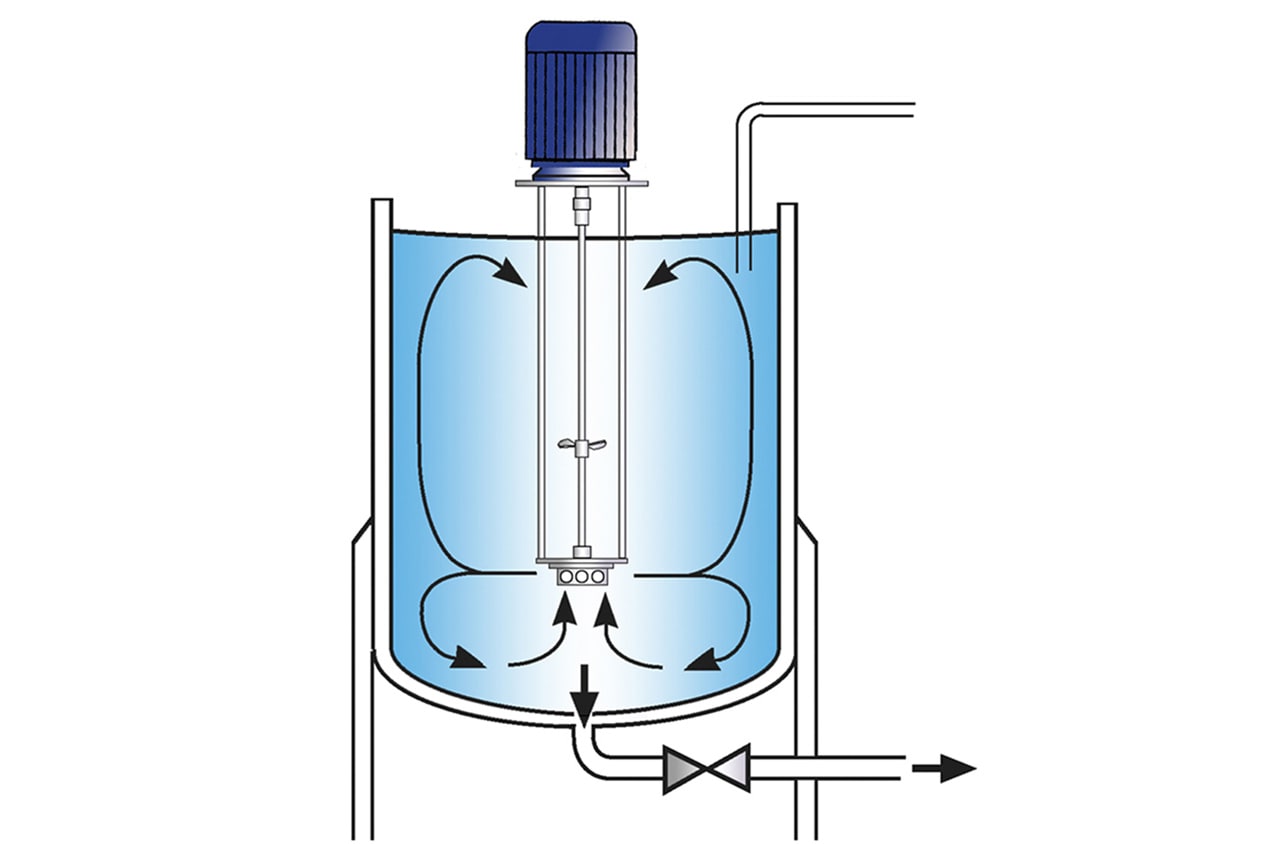

High Shear Batch Mixers

- Suitable for batch sizes up to 300 US gallons

- Can be used on mobile floor stands

- Sealed units available for pressure/vacuum operation

- Small units available for R&D and pilot production

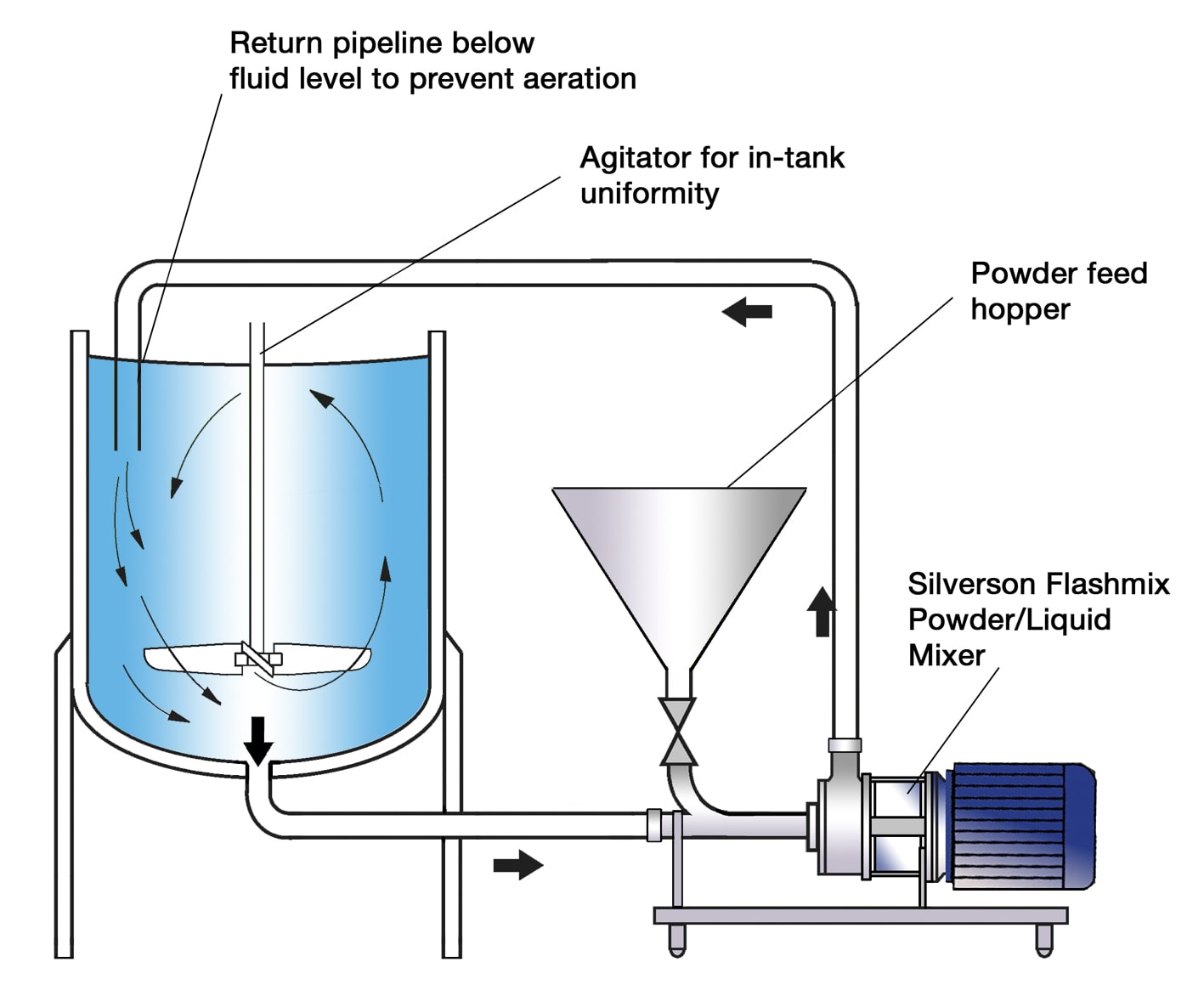

Silverson Flashmix

- Ideal for larger batches

- Viscous liquids and gels can be fed into the system via the hopper

- They can also be pumped directly into the fluid stream via a manifold

- Minimized aeration

- Minimized cleaning requirements

- Minimum operator input required

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

Không có nhận xét nào:

Đăng nhận xét