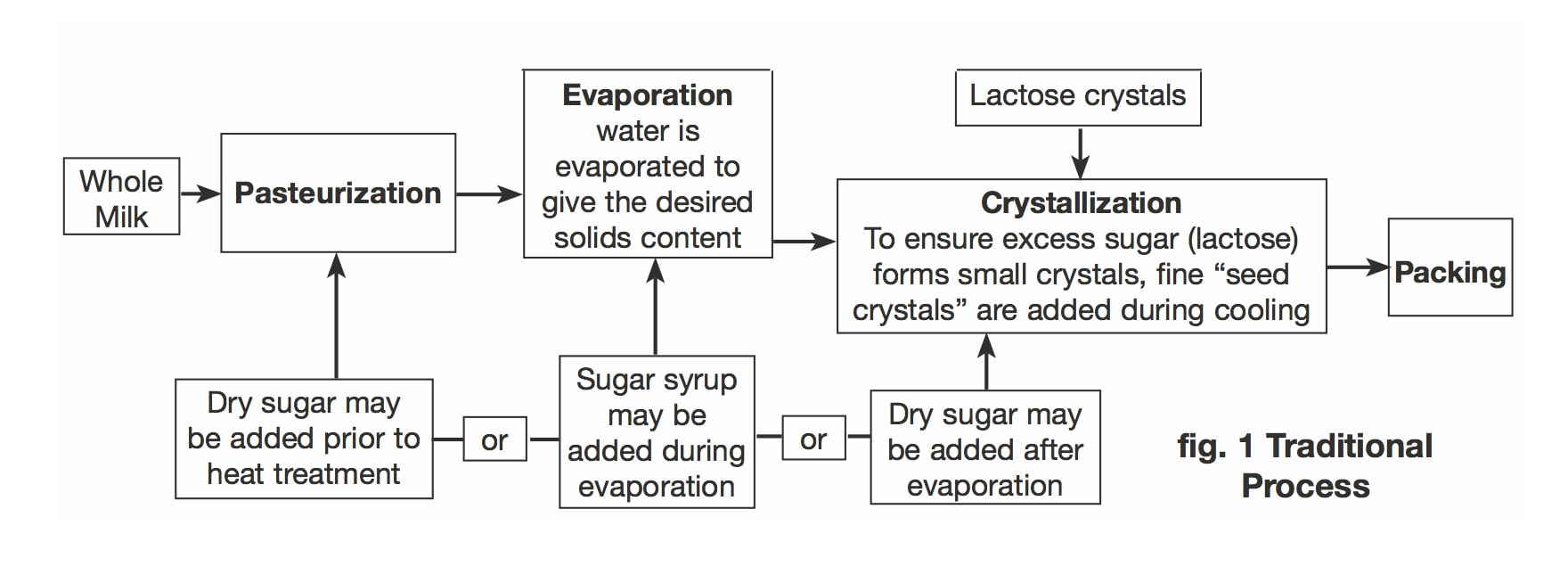

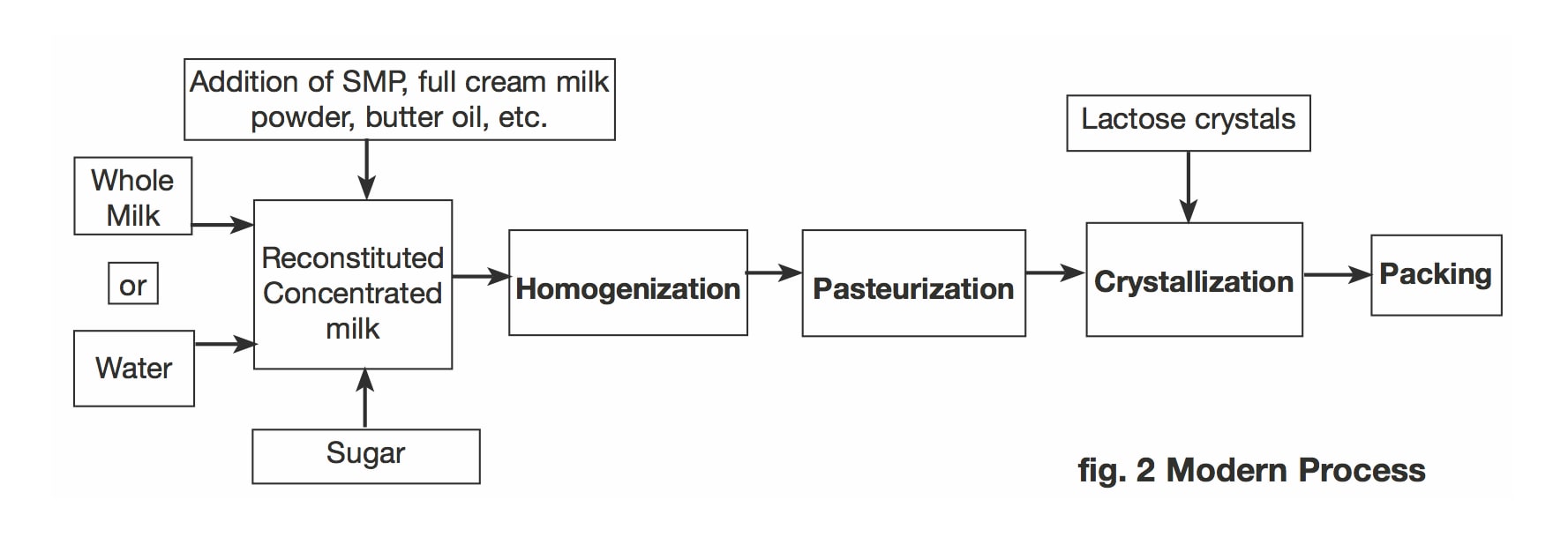

Traditionally SCM was produced by adding sugar to whole milk and removing water by evaporation (fig. 1). Increasingly, SCM is made by addition of skim milk powder (SMP), butter oil and sugar to milk or water to increase the solids to the desired level. Depending on the amount added, this can shorten or even eliminate the evaporation stage (fig. 2).

The Problem

The process is subject to a number of problems:

- Skim milk powder and full cream milk powder are very cohesive and difficult to wet out, making handling and controlled powder addition difficult.

- The powders will form agglomerates when added to the liquid. Agitators do not produce sufficient shear to rapidly break these down.

- Dissolving high concentration of sugar using agitators is a slow process.

- High pressure homogenization may be required to ensure the product is agglomerate-free and properly dispersed.

The Solution

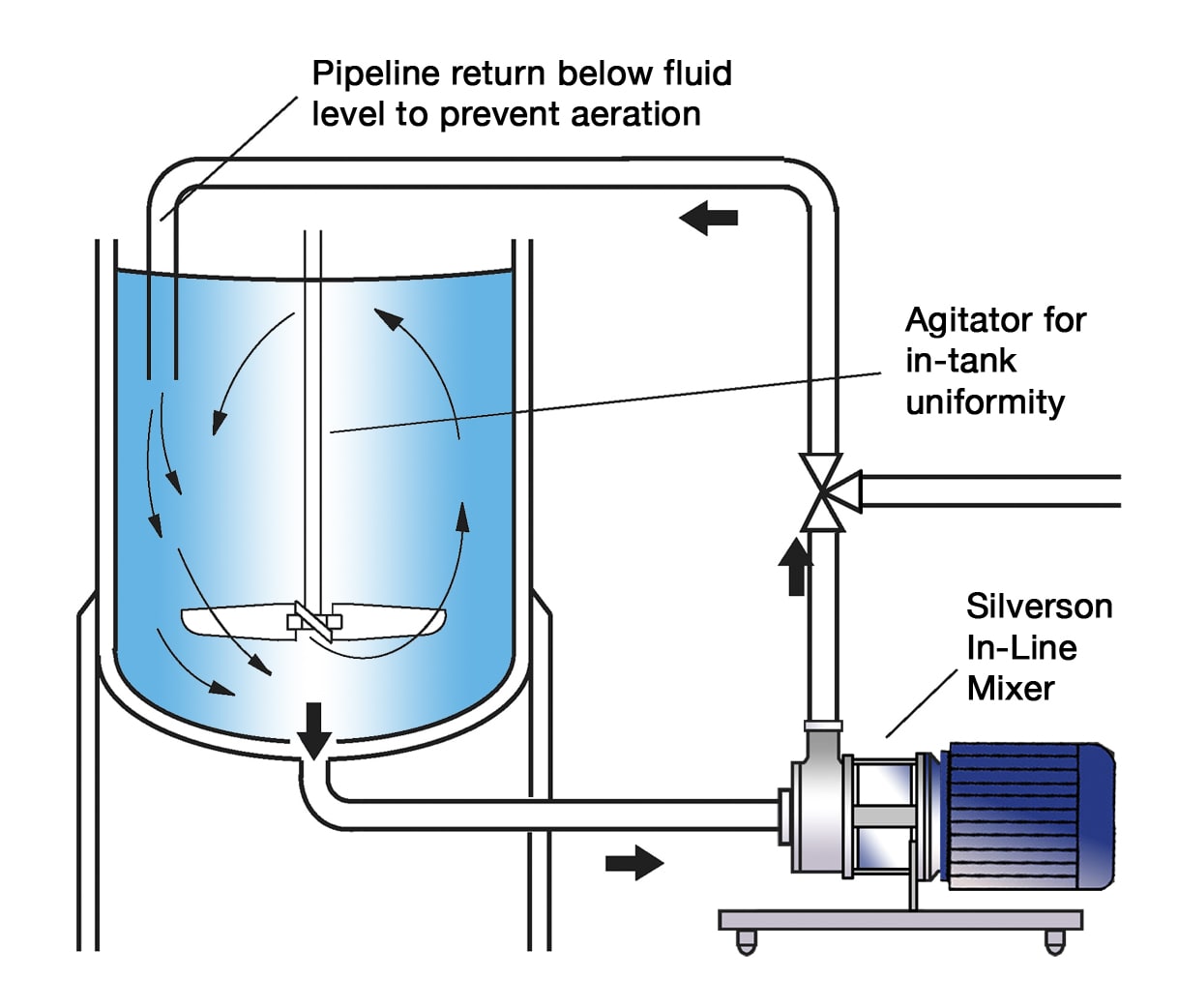

These problems can be overcome by using a Silverson mixer. In most cases the sugar would be added straight into the vessel, being dispersed by a Silverson Batch mixer or a simple agitator working in conjunction with an In-Line mixer. The high shear action of the rotor/stator workhead accelerates the dissolving process. The milk powder can be added in the same manner, or, for large volumes, using the Flashmix powder/liquid mixing system.

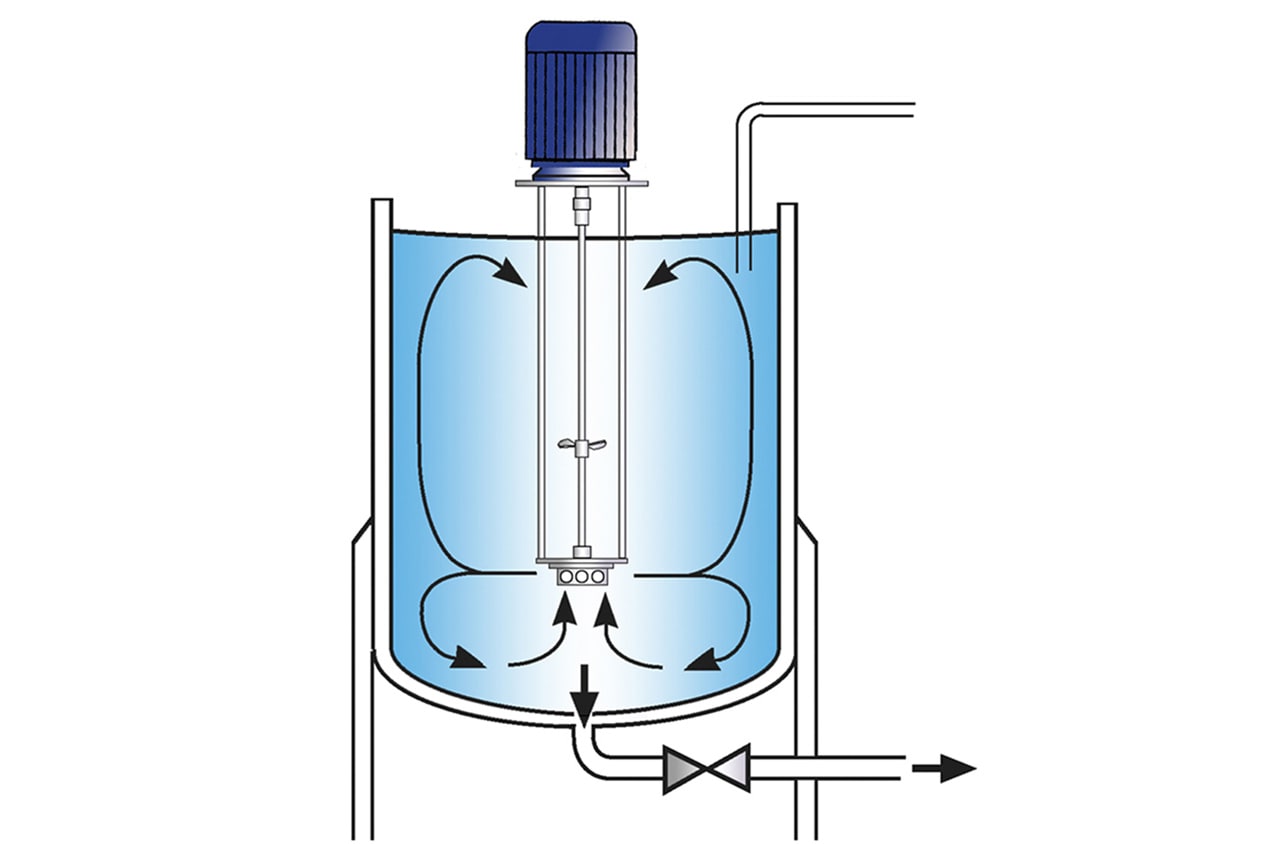

These advantages stem from the 3 stage mixing/shearing action generated by the rotor/stator workhead, which operates as follows:

Stage 1

The high speed rotation of the rotor blades creates a powerful suction which draws the milk and sugar granules/milk powder from the vessel into the workhead.

Stage 2

Centrifugal force drives the materials to the periphery of the workhead where they are subjected to a milling action in the gap between the rotor and the stator wall. Agglomerates in the milk powder are broken down as the powder is finely dispersed into the milk.

Stage 3

The product is forced out through the stator as fresh materials enter the workhead. In a short mixing cycle all the material passes through the workhead, progressively reducing sugar granule size and exposing an increasing surface area to the milk, accelerating the dissolving process.

The Advantages

- Agglomerate-free dispersion of milk powder.

- Improved premix quality reduces homogenization time and can eliminate the need for high pressure homogenization.

- Dramatic reduction in mixing times.

- The high concentration of solids made possible by high shear mixing can eliminate the evaporation stage.

- The combination of granule size reduction and vigorous mixing greatly accelerates dissolving the sugar.

High Shear Batch Mixers

- Suitable for batches up to 300 US gallons

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

High Shear In-Line Mixers

- Ideal for larger batches

- Easily retrofitted to existing plant

- Must be used in conjunction with an efficient in-tank agitator to wet out powder

- Aeration free

- Self-pumping

- Can be used to discharge vessel

- Ultra Sanitary models available

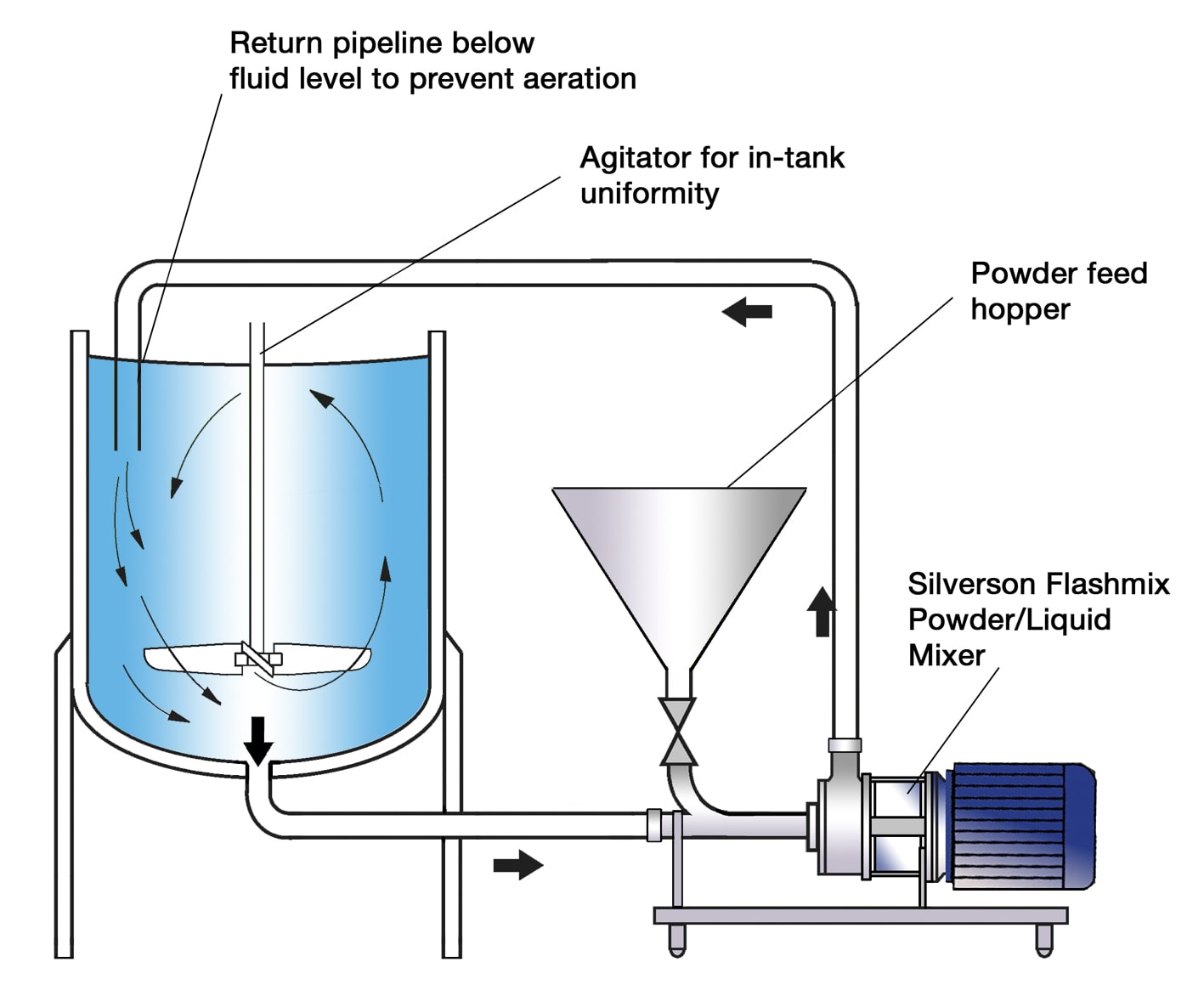

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating very large volumes of milk powder

- Sugar is then added straight into the vessel. Recirculation through the In-Line mixer accelerates the dissolving process

- Minimized aeration

- Minimized cleaning requirements

- Controlled powder addition rate

- Minimum operator input required

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

Không có nhận xét nào:

Đăng nhận xét