MODEL: 425LS

VẬT LIỆU THÉP KHÔNG GỈ GRADE 316L

MOTOR 5.5 HP, 3000 RPM, MOTOR CHỐNG CHÁY NỔ theo yêu cầu

Đầu khuấy chuyên dụng 8 dao

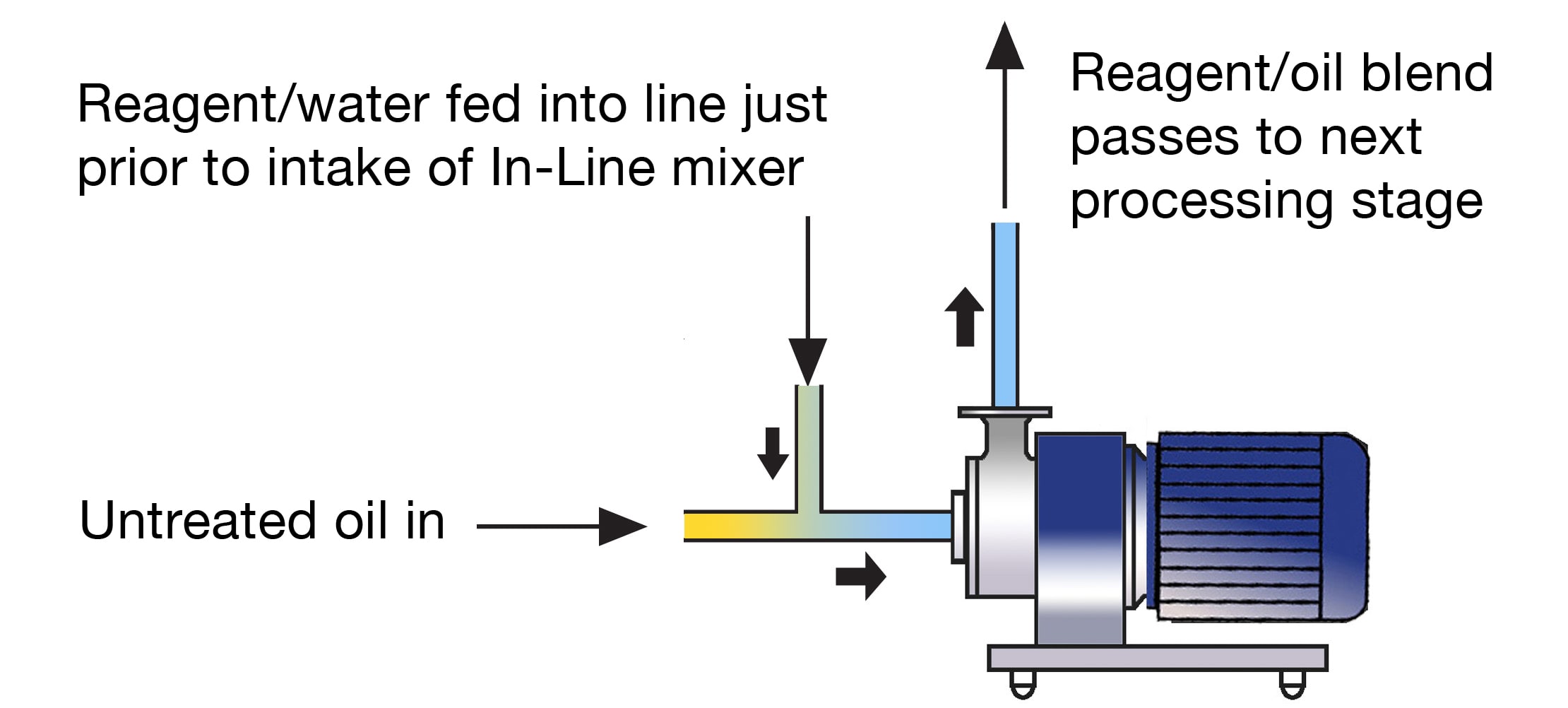

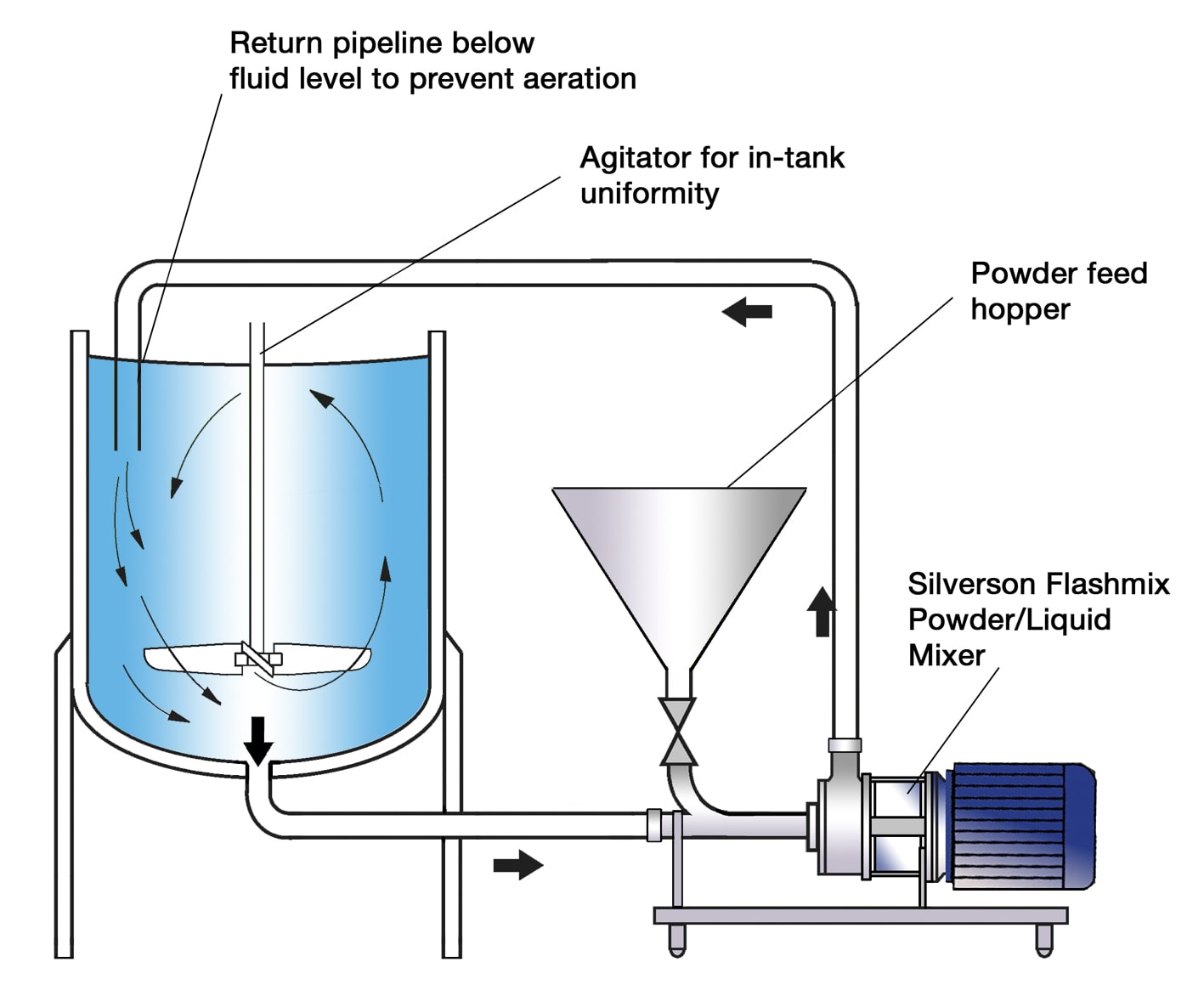

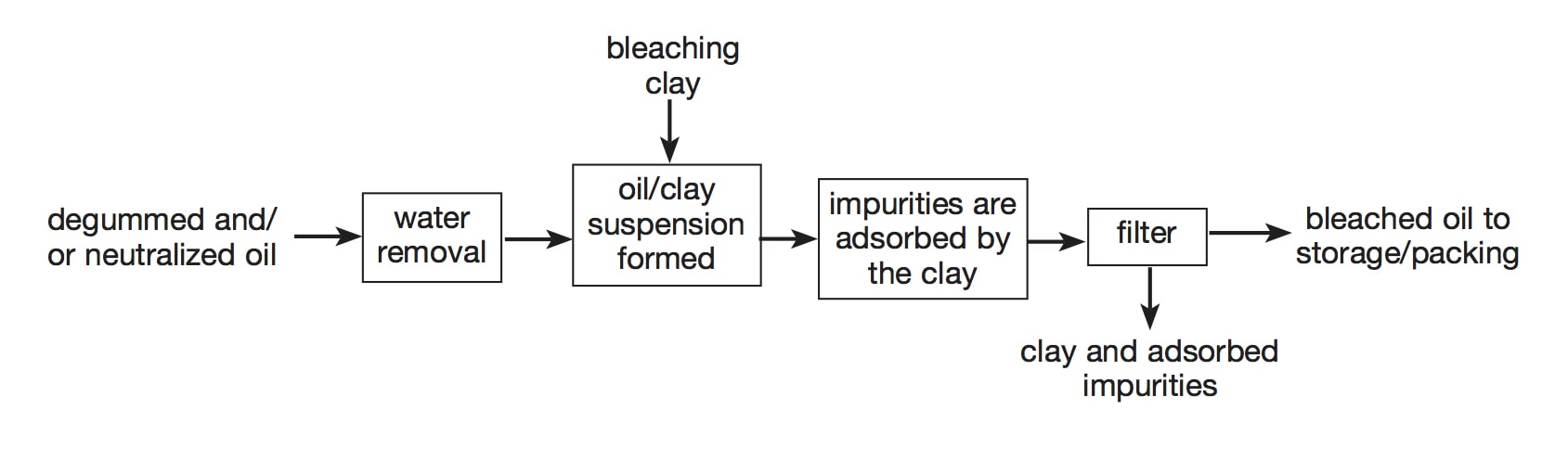

The wide range of oils processed by these methods leads to considerable variations in process requirements:

- Oils which tend to emulsify may be held in a vessel after mixing with the reagent to allow the emulsion to break before passing to the separator.

- In the degumming process the typical acid addition is 0.1 - 1%. Phosphoric acid is most commonly used, although citric acid is suitable for some oils.

- Process temperature is typically in the range of 120 - 160ºF (50 - 70ºC).

- Neutralization process temperature may be higher, up to 200ºF (95ºC).

- The strength of the sodium hydroxide solution varies according to the acid content and oil type.

- During bleaching, a filter aid such as diatomaceous earth may be added to prevent the finer clay particles from blinding the filter medium.

Không có nhận xét nào:

Đăng nhận xét